Maintaining toilet partitions is more than just a chore; it’s a critical aspect of managing a clean, hygienic, and welcoming restroom environment. Whether you’re overseeing a bustling office space or a high-traffic commercial venue, the state of your restrooms can leave a lasting impression on visitors and staff alike. Toilet partitions, given their constant use and exposure to moisture, are prone to wear and tear, making regular maintenance a must to ensure longevity and functionality.

In this guide, we’ll delve into the various materials commonly used in toilet partitions. Each material has its unique cleaning requirements and maintenance needs, which we’ll explore to help you make informed decisions about the care of your restroom facilities. By the end of this guide, you’ll have a comprehensive understanding of how to keep your toilet partitions in top condition, ensuring they remain clean, durable, and functional for years to come.

Understanding Your Toilet Partitions

Materials Used in Toilet Partitions and Their Characteristics

- Metal Partitions: Known for their durability and cost-effectiveness. Ideal for high-traffic areas but susceptible to rust if not properly maintained.

- Plastic Laminate Partitions: Offer a wide range of design options and are resistant to graffiti; however, they can be prone to moisture damage over time.

- Solid Plastic Partitions: Extremely durable and resistant to moisture, making them perfect for wet environments. Easy to clean but can be more expensive upfront.

- Stainless Steel Partitions: Provide a sleek, modern look and are highly resistant to corrosion and vandalism. They require regular cleaning to maintain their shine and prevent fingerprint marks.

- Phenolic Partitions: Known for their strength and resistance to bacteria, water, and vandalism. They are suitable for high-traffic and humid environments but come at a higher cost.

Each material comes with its own set of maintenance needs and potential issues. For instance, metal partitions may require more attention to prevent rust, while plastic laminate partitions need protection from excessive moisture. Recognizing the signs of wear and tear, such as scratches, dents, and fading, is crucial in determining the right care and maintenance routine for your toilet partitions.

Daily Maintenance Tips for Longevity

Maintaining the cleanliness and functionality of toilet partitions requires a daily commitment to proper care. Here are some essential tips to help prevent buildup and damage:

- Routine Cleaning Practices: Regularly wipe down partitions with a mild soap and water solution to remove dirt and grime. For more stubborn stains, use a non-abrasive cleaner that’s suitable for the partition material.

- Recommended Cleaning Agents and Tools: Avoid harsh chemicals and abrasive tools that can damage the partition surfaces. Instead, opt for soft cloths and gentle cleaners labeled safe for use on your specific partition material.

- Addressing Common Issues: For graffiti, use a graffiti remover designed for the partition’s material. For scratches and dents, repair kits can be used to minimize visibility and prevent further damage.

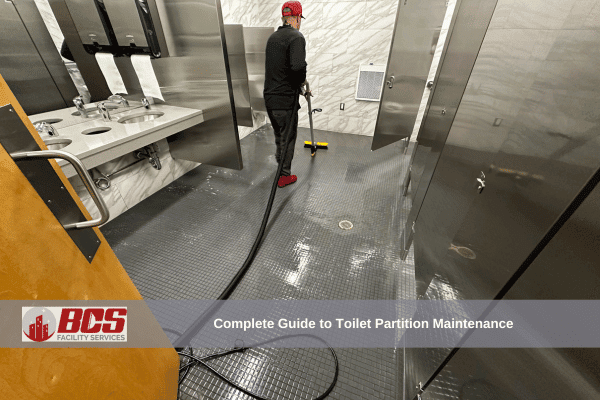

Deep Cleaning Strategies for Toilet Partitions

To ensure your toilet partitions remain in pristine condition, incorporating deep cleaning sessions into your maintenance routine is essential. Here’s how to approach deep cleaning:

- Step 1: Start with a thorough inspection of the partitions for any signs of damage or wear.

- Step 2: Use a mild detergent solution to clean the surfaces, paying extra attention to high-touch areas such as door handles and locks.

- Step 3: For stainless steel partitions, apply a stainless steel cleaner to maintain the material’s natural shine and prevent oxidation.

- Step 4: Rinse all surfaces with clean water and dry thoroughly to prevent water spots and streaks.

- Step 5: Assess the need for repairs or replacements for any damaged components.

Deep cleaning should be performed at least once a month or more frequently depending on the level of traffic and usage your restrooms receive. Special considerations, such as avoiding corrosive cleaners on sensitive materials like stainless steel, are crucial to prevent damage during the cleaning process.